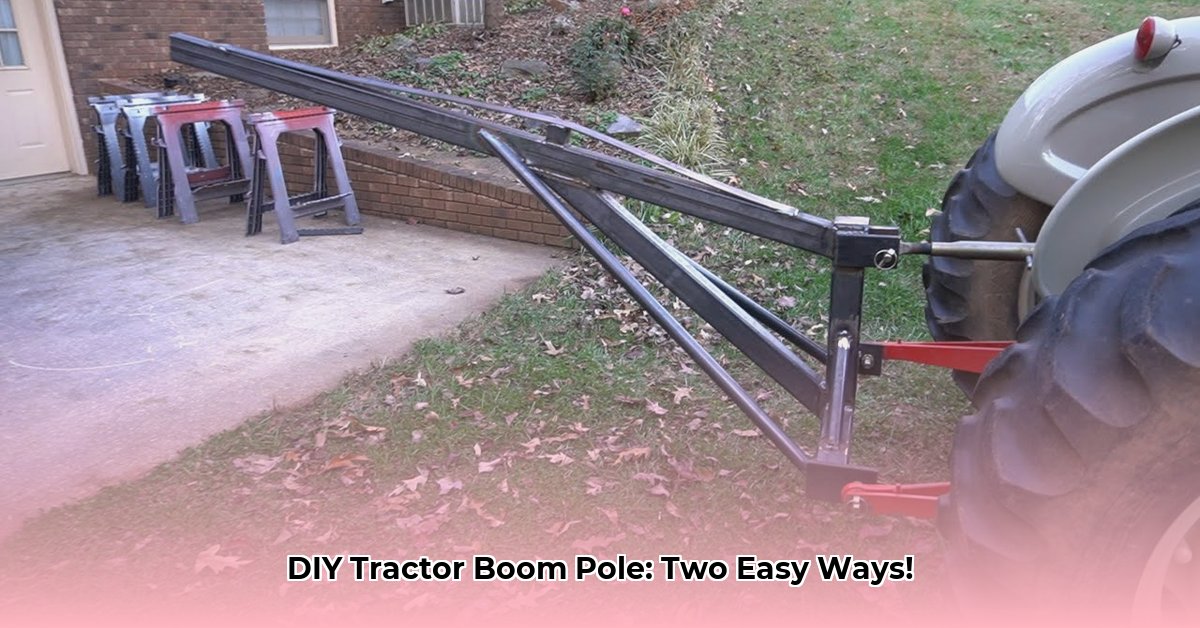

Need a boom pole for your tractor but don't want to pay exorbitant prices? Building your own is a cost-effective solution, offering a satisfying sense of accomplishment. This comprehensive guide details two straightforward methods—welding and bolting—allowing you to choose the best approach based on your skills and resources. We'll cover materials, construction, and crucial safety considerations, ensuring you end up with a durable, functional boom pole. For even more detailed instructions, check out this helpful guide.

Method A: The Robust Welded Boom Pole

This method prioritizes strength and longevity, ideal for those comfortable with welding and needing a boom for heavy-duty tasks. The key is using robust materials—thick steel tubing and angle iron—to create a highly resilient boom.

Materials Required:

- Heavy-duty steel tubing (approximately 2.5 inches diameter, 1/8-inch wall thickness) – forms the boom's backbone.

- Heavy-duty steel angle iron (approximately 2 inches x 2 inches, 3/16-inch thickness) – provides crucial structural support.

- MIG welder (recommended for this project). Consider renting if you don't own one.

- Grinder with cutting and grinding wheels – for precise metal shaping and weld cleanup.

- Measuring tape, level, and sturdy clamps – for accurate measurements and secure assembly during welding.

Construction Steps:

- Precise Cutting: Measure and cut the steel tubing and angle iron to your exact specifications. Accuracy is paramount for a functional boom.

- Frame Welding: Weld the angle iron to the tubing, forming the main frame. Ensure strong, even welds for a rigid structure. Multiple passes per weld are recommended.

- Weld Reinforcement: Reinforce welded joints with additional welds for enhanced durability and safety. This significantly increases long-term reliability.

- Hitch Attachment: Securely attach the 3-point hitch components to the boom, ensuring a tight fit to prevent movement during operation.

- Load Testing: Begin with lighter loads to assess strength and stability. Gradually increase weight, always prioritizing safety. Isn't it reassuring to know your boom can handle the job?

Advantages:

- Exceptional strength and rigidity for heavy loads.

- Long-lasting durability, providing years of reliable service.

Disadvantages:

- Requires welding experience and equipment.

- Higher initial cost due to materials and specialized tools.

Method B: The Bolted Boom Pole—A Simpler Approach

This method is perfect for beginners lacking welding experience, offering a simpler and more accessible solution. While less robust than a welded boom, it's still functional for many applications.

Materials Needed:

- Lighter-gauge steel tubing (approximately 2 inches diameter, 1/4-inch wall thickness).

- Lighter-gauge steel angle iron (approximately 2 inches x 2 inches, 3/16-inch thickness).

- High-strength bolts, nuts, and washers – use high-quality fasteners for secure connections.

- Drill with appropriate drill bits.

- Accurate measuring tools (tape measure, level, square).

Assembly Instructions:

- Accurate Measurements: Precise measurements are critical. Double-check before proceeding.

- Hole Drilling: Drill holes in the tubing and angle iron for the bolts. Ensure perfect alignment for a secure fit.

- Assembly: Assemble the frame using the bolts, tightening securely to minimize movement.

- Added Bracing: Incorporate additional bracing (e.g., more angle iron) to enhance rigidity.

- Hitch Connection: Attach the 3-point hitch components, thoroughly checking for stability before use.

Pros:

- Easier construction—no welding required.

- Lower initial cost due to less expensive materials and tools.

Cons:

- Less rigid than a welded boom, especially under heavy loads.

- Requires regular bolt tightening to maintain safety and prevent loosening.

A Detailed Comparison: Welded vs. Bolted Boom Poles

| Feature | Welded Boom (Method A) | Bolted Boom (Method B) |

|---|---|---|

| Strength | High | Medium |

| Rigidity | High | Medium |

| Cost | Higher | Lower |

| Time Investment | Longer | Shorter |

| Skill Required | Welding skills | Basic fabrication skills |

Safety Precautions: Always Prioritize Safety!

Regardless of the chosen method, prioritize safety:

- Wear appropriate safety glasses, gloves, and hearing protection (especially when welding).

- Thoroughly inspect the boom pole before each use.

- Begin with lighter loads to test stability. Gradually increase weight as confidence grows.

- A poorly constructed boom poses serious risks.

This guide provides a foundation for building your own tractor boom pole. Adapt instructions to your specific needs, and always prioritize safe practices. Happy building!